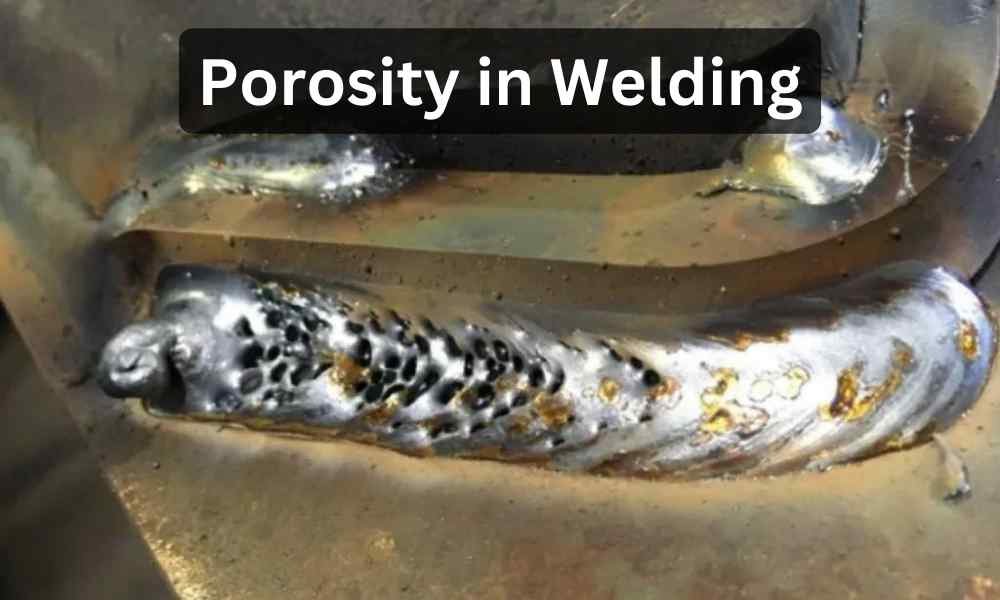

In welding, porosity refers to the presence of tiny cavities or voids within the weld metal. These voids are usually gas pockets trapped in the solidifying weld metal or inclusions of slag. Porosity is undesirable because it can weaken the weld by reducing its effective cross-sectional area and creating potential stress concentration points.

Why Does Porosity Form

Porosity in welding primarily results from the presence of gas pockets or voids trapped within the solidifying weld metal. These gas pockets can originate from various sources and conditions during the welding process:

1. Contaminants on Base Metal

Surface contaminants such as moisture, oil, grease, paint, or rust on the base metal can vaporize when exposed to the high temperatures of welding. This vaporization releases gas, which becomes trapped in the weld pool as it solidifies, forming porosity.

2. Contaminants in Filler Material

If the filler material is contaminated with moisture, grease, or other substances, these contaminants can vaporize during welding. This contributes to the formation of gas pockets in the weld.

3. Shielding Gas Issues

Improper shielding gas flow rate or composition can lead to inadequate coverage of the weld pool. This inadequacy allows atmospheric gases (such as oxygen, nitrogen, or hydrogen) to react with the molten metal, forming gas bubbles that get trapped in the weld as it solidifies.

4. Welding Technique and Parameters

Incorrect welding parameters such as excessive heat input, improper arc length, or inappropriate welding speed can affect the molten metal’s ability to release trapped gases. Rapid solidification or insufficient time for gases to escape can lead to porosity.

5. Base Metal Composition

Certain metals, alloys, or metal conditions (e.g., high sulfur or phosphorus content) are more prone to generating gas when melted. These gases can become trapped in the weld pool if not properly managed.

6. Electrode Conditions

In processes that use consumable electrodes, such as stick welding (SMAW) or flux-cored arc welding (FCAW), moisture or contaminants in the electrode coating can vaporize during welding. This contributes to porosity.

Impact of Porosity on Weld Quality

Porosity in welding significantly affects the quality and durability of welds. The presence of gas pockets or voids within the weld metal can compromise the weld’s strength and integrity. Understanding the impact of porosity is crucial for ensuring reliable and long-lasting welds in various applications. Porosity in welding can significantly impact the quality and integrity of welds in several ways:

1. Reduced Strength

Porosity creates voids or gas pockets within the weld metal. These voids act as stress concentrators, weakening the weld and reducing its overall strength. In critical applications, such as structural welding or pressure vessels, weakened welds can compromise the safety and reliability of the welded structure.

2. Decreased Ductility and Toughness

Welds with porosity are less ductile and less tough compared to welds without porosity. This reduced ductility and toughness can lead to brittleness and susceptibility to cracking, especially under dynamic or impact loading conditions.

3. Potential for Cracking

The presence of gas pockets within the weld can create stress concentrations that promote cracking, particularly under cyclic loading or when exposed to thermal stresses. Cracks originating from porosity can propagate through the weld and into the base metal, further compromising the structural integrity.

4. Corrosion Susceptibility

Porosity provides pathways for moisture, oxygen, and other contaminants to penetrate into the weld metal. This can accelerate corrosion processes, leading to premature failure of the weld joint in corrosive environments.

5. Aesthetic and Surface Quality

Porosity can also affect the appearance and surface quality of welds. In applications where aesthetics are important (such as architectural or automotive welding), porosity can be cosmetically unacceptable, requiring additional time and effort for rework or finishing.

6. Weld Inspection Challenges

Detection of porosity during visual inspection or non-destructive testing (NDT) can be challenging, especially if the porosity is internal or if it occurs in hard-to-reach areas. This can lead to uncertainties about the weld quality and may necessitate more extensive inspection methods.

How to Prevent Porosity

Preventing porosity is essential for achieving high-quality welds and maintaining structural integrity. Effective measures include ensuring clean base metals, using dry filler materials, and optimizing welding parameters. By addressing the root causes of porosity, welders can enhance the durability and performance of their welds. Here are some effective measures to prevent porosity:

1. Cleanliness of Base Metal

Thoroughly clean and degrease the surfaces of the base metals before welding. Remove any contaminants such as oil, grease, rust, paint, or dirt that could vaporize and contribute to porosity during welding.

2. Dry Filler Materials and Electrodes

Ensure that filler materials (welding rods, wires, fluxes) and consumable electrodes are stored in dry conditions. Moisture in filler materials can vaporize during welding, causing gas pockets in the weld metal.

3. Proper Shielding Gas Selection and Flow

Use the appropriate shielding gas for the welding process and materials being welded (e.g., argon, helium, carbon dioxide, or mixtures). Check and maintain the correct flow rate and gas coverage to protect the weld pool from atmospheric contamination.

4. Optimize Welding Parameters

Follow recommended welding procedures and parameters specified by welding procedure specifications (WPS). Properly adjust parameters such as voltage, current, arc length, travel speed, and heat input to ensure good weld pool control and adequate gas escape.

5. Joint Fit-Up and Preparation

Ensure proper fit-up of the joint with minimal gaps or misalignment. Poor fit-up can lead to inadequate shielding gas coverage or trapping of contaminants, increasing the likelihood of porosity.

6. Reduce Moisture and Humidity

Minimize exposure of welding materials and equipment to high humidity environments. Moisture can condense on surfaces and materials, potentially leading to porosity issues.

7. Use Backing Gas or Flux

Employ backing gas (purge gas) when welding materials susceptible to oxidation on the back side of the weld joint. Alternatively, use fluxes in processes like flux-cored arc welding (FCAW) to help protect the weld metal from atmospheric contamination.

8. Inspect and Maintain Equipment

Regularly inspect welding equipment, including gas lines, regulators, and torches, to ensure they are clean and in good working condition. Malfunctioning equipment can contribute to inconsistent shielding gas flow and quality.

9. Training and Qualification

Ensure that welders are properly trained and qualified to perform welding tasks according to industry standards and specifications. Knowledgeable welders can effectively manage welding parameters and respond to potential porosity issues during welding.

10.Quality Control and Inspection

Implement thorough inspection procedures, including visual inspection and non-destructive testing (NDT) methods, to detect and address porosity early. Prompt identification and correction of porosity can prevent further defects and ensure weld quality.

Solutions for Porosity in Welding

Addressing porosity in welding involves implementing targeted solutions to mitigate its effects. Effective strategies include improving base metal preparation, optimizing welding parameters, and ensuring proper equipment maintenance to achieve defect-free welds. When porosity occurs in welding, there are several strategies and solutions that can be implemented to mitigate or eliminate this issue:

1. Improve Base Metal Preparation

Clean and degrease base metals thoroughly before welding to remove contaminants such as oil, grease, rust, and dirt. Proper surface preparation helps prevent the introduction of gases into the weld pool.

2. Use Dry and Clean Filler Materials

Store filler materials and consumable electrodes in dry conditions to prevent moisture absorption. Moisture in filler materials can vaporize during welding, causing porosity. If using stick electrodes, ensure they are baked in accordance with manufacturer recommendations to remove moisture.

3. Optimize Shielding Gas Coverage

Select the appropriate shielding gas and ensure proper flow rates and coverage to protect the weld pool from atmospheric contamination. Use gas flow meters and regulators to maintain consistent gas flow during welding.

4. Adjust Welding Parameters

Optimize welding parameters such as voltage, current, arc length, travel speed, and heat input according to welding procedure specifications (WPS). Proper parameter settings promote good weld pool control and effective gas escape, reducing the likelihood of porosity.

5. Implement Backing Gas or Flux

Use backing gas (purge gas) for welding materials susceptible to oxidation on the back side of the weld joint. Backing gas helps create an inert atmosphere and prevents atmospheric gases from entering the weld pool. Alternatively, fluxes in processes like flux-cored arc welding (FCAW) can shield the weld metal from contamination.

6. Preheat and Maintain Joint Fit-Up

Preheat the base metal if required to reduce the presence of moisture and contaminants. Ensure proper joint fit-up with minimal gaps or misalignment, as poor fit-up can lead to inadequate shielding gas coverage and porosity.

7. Inspect and Maintain Equipment

Regularly inspect welding equipment, including gas lines, regulators, torches, and welding machines, to ensure they are clean, free of leaks, and functioning properly. Malfunctioning equipment can contribute to inconsistent shielding gas flow and quality issues.

8. Use Correct Technique and Control Environment

Employ proper welding techniques, including maintaining a steady arc and controlling the welding environment to minimize drafts and airflow that can introduce contaminants into the weld area.

9. Training and Qualification

Ensure welders are adequately trained and qualified to perform welding tasks according to industry standards. Knowledgeable welders can identify potential causes of porosity and take corrective actions promptly.

10. Quality Control and Inspection

Implement stringent quality control measures, including visual inspection and non-destructive testing (NDT) methods such as ultrasonic testing or radiographic testing, to detect porosity and other defects early. Prompt identification and remediation of porosity issues help ensure weld quality and integrity.

Welding Processes and Porosity

Porosity in welding varies by process but generally stems from inadequate shielding gas coverage, contaminants, or improper parameters. In Gas Metal Arc Welding (GMAW), issues like insufficient gas flow or dirty surfaces can lead to porosity. Gas Tungsten Arc Welding (GTAW) faces similar problems with shielding gas purity and electrode cleanliness. Shielded Metal Arc Welding (SMAW) and Flux-Cored Arc Welding (FCAW) are prone to porosity from electrode conditions and gas coverage. Preventive actions include proper gas settings, clean surfaces, and optimal welding parameters to ensure strong welds free of porosity.

1. Porosity in MIG Welding

Porosity in MIG welding often results from inadequate shielding gas coverage or contaminants on the base metal or filler wire. Improper shielding gas flow or composition can allow atmospheric gases to enter the weld pool, forming gas bubbles that become trapped and cause porosity. Contaminants like oil, grease, or rust can also vaporize during welding, releasing gas into the weld metal. Maintaining proper gas settings, ensuring clean surfaces, and controlling welding parameters are crucial for preventing porosity and ensuring high-quality welds.

2. Porosity in TIG Welding

Porosity in TIG welding often stems from inadequate shielding gas coverage or impurities in the gas. Insufficient flow rates or contaminants like oxygen and nitrogen can infiltrate the weld pool, creating gas bubbles that lead to porosity. Contaminated tungsten electrodes or filler rods can also introduce gases during welding. Maintaining clean materials, proper gas settings, and precise welding parameters are essential for preventing porosity and ensuring strong, defect-free TIG welds.

3. Porosity in Arc Welding

Porosity in arc welding, whether in processes like SMAW or GMAW, often results from inadequate shielding gas coverage or contamination. In SMAW, moisture or impurities in the electrode coating can vaporize, creating gas pockets in the weld. Similarly, in GMAW, improper shielding gas flow or composition can allow atmospheric gases into the weld pool, causing gas entrapment and porosity. Maintaining clean base metals, using dry electrodes or filler materials, and ensuring proper shielding gas settings are essential to prevent porosity. Adjusting welding parameters such as voltage, current, and travel speed also helps minimize porosity and maintain weld quality.

Types of Porosity and Their Characteristics

Understanding the different types of porosity in welding is crucial for diagnosing and addressing weld defects. Each type of porosity has unique characteristics and causes that impact the weld’s quality and performance. Porosity in welding can manifest in various forms, each with distinct characteristics that affect the weld’s integrity and appearance:

1. Surface Porosity

- Characteristics:

- Appears as small, shallow depressions or holes on the surface of the weld bead.

- These pores are typically visible to the naked eye.

- Size and density can vary depending on the severity of the porosity.

- Causes:

- Often caused by contaminants such as oil, grease, rust, or moisture on the surface of the base metal or filler material.

- Contaminants vaporize during welding, leaving behind voids in the solidified weld metal.

2. Subsurface Porosity

- Characteristics:

- Less visible on the surface of the weld but detectable through non-destructive testing methods like ultrasonic testing.

- Appears as clusters or networks of interconnected voids within the weld metal.

- Causes:

- Typically results from gases (such as hydrogen, nitrogen, or oxygen) trapped within the weld pool as it solidifies.

- Can occur due to inadequate shielding gas coverage, improper welding parameters, or contamination of the filler material.

3. Pipe Porosity

- Characteristics:

- Appears as cylindrical voids or tunnels that extend through the weld metal.

- Void diameters and lengths can vary and are typically aligned with the direction of welding.

- Causes:

- Often associated with flux-cored arc welding (FCAW) or submerged arc welding (SAW).

- Results from improper flux coverage or inadequate gas shielding during welding, allowing gases to become trapped and form elongated voids.

4. Crater Pipe Porosity

- Characteristics:

- Occurs at the crater (end) of a weld bead and resembles a pipe or tunnel extending from the crater into the weld metal.

- Causes:

- Happens when the weld crater is not properly filled at the end of the weld bead.

- Insufficient gas shielding during crater filling or improper crater control can lead to gas entrapment and the formation of these elongated voids.

Effects of Porosity on Weld Quality

Porosity can severely undermine weld quality, affecting strength, durability, and appearance. Understanding its impact is essential for ensuring the structural integrity and reliability of welded joints. Porosity in welding can have significant negative effects on weld quality and performance:

1. Reduced Strength

Porosity creates voids or gas pockets within the weld metal, which act as stress concentrators. These voids weaken the weld and reduce its overall strength. In critical applications such as structural welding or pressure vessels, weakened welds can compromise the structural integrity and reliability of the welded component.

2. Decreased Ductility and Toughness

Welds affected by porosity are often less ductile and less tough compared to porosity-free welds. Reduced ductility and toughness make the weld more susceptible to cracking, especially under dynamic or impact loading conditions. This compromises the weld’s ability to withstand mechanical stresses and strains.

3. Increased Susceptibility to Cracking

Porosity provides nucleation sites for cracks to initiate and propagate. Stress concentrations around the voids can lead to the development of cracks, particularly under cyclic loading or thermal stresses. Cracks originating from porosity can propagate through the weld and into the base metal, further compromising the weld’s structural integrity.

4. Corrosion Vulnerability

Porosity creates pathways for moisture, oxygen, and other contaminants to penetrate into the weld metal. This accelerates corrosion processes, leading to premature deterioration of the weld joint in corrosive environments. The presence of porosity reduces the effectiveness of protective coatings or inhibitors, exacerbating corrosion susceptibility.

5. Aesthetic and Surface Quality Issues

Porosity affects the appearance and surface quality of welds, which can be critical in applications where aesthetics are important (e.g., architectural or automotive welding). Porosity can result in a rough or uneven surface finish, which may require additional time and effort for rework or finishing to meet visual standards.

6. Challenges in Inspection and Quality Assurance

Detecting and assessing porosity during inspection can be challenging, especially if the porosity is internal or located in hard-to-reach areas of the weld. Porosity reduces the overall reliability of non-destructive testing (NDT) methods, potentially leading to uncertainties about the weld quality and necessitating more extensive inspection procedures.

FAQs

1. What does porosity mean in welding?

Porosity in welding refers to the presence of gas pockets or voids within the weld metal. These voids can result from trapped gases like hydrogen, oxygen, or nitrogen during the welding process, compromising the weld’s integrity and mechanical properties.

2. What is a porosity defect?

A porosity defect in welding is characterized by the formation of gas voids or bubbles within the weld metal. These voids weaken the weld, reducing its strength, ductility, and resistance to cracking. Porosity defects can lead to structural failures and are undesirable in high-quality welds.

3. How do you prevent weld porosity?

To prevent weld porosity, ensure thorough cleaning of base metals to remove contaminants. Use dry and clean filler materials and electrodes, maintain proper shielding gas coverage with correct flow rates, and optimize welding parameters such as voltage, current, and travel speed. These measures help minimize gas entrapment during welding.

4. What is the reason for porosity?

Porosity in welding occurs due to several reasons, including inadequate shielding gas coverage, contamination on base metals or filler materials, and improper welding parameters. Moisture, oil, rust, or paint on surfaces can vaporize and release gases during welding, which then get trapped in the solidifying weld metal, causing porosity.